Common methods and applications of several silicon carbide refractory materials

Different types of silicon carbide refractories can be made by combining silicon carbide with different combination phases. Common bonding forms are: clay bonding, oxide bonding, mullite bonding, silicon nitride (Si3N4) bonding, recrystallization (R-SiC), and reaction sintering silicon infiltration, etc. The properties of silicon carbide refractories depend on the binding phase.

①Clay bonded silicon carbide products (Clay-SiC)

is the most common silicon carbide refractory material. It is mixed with 10%~40% bonded clay and silicon carbide particles, pressed or rammed, and then fired in a general kiln. Clay-SiC is used in the muffle board of zinc smelting furnace and ceramic kiln.

②Oxide bonded silicon carbide products (SiO2-SiC)

In fact, SiO2 is used as the binding phase. It is a mixture of 5%~10% SiO2 powder or fine quartz powder and SiC particles. Sometimes a flux is needed, and it is fired in a general kiln after pressing and molding. Its characteristic is that the SiO2 film is wrapped on the SiC particles during the firing and use process, the oxidation resistance is much better than that of Clay-SiC, and the high temperature strength is also high. This kind of product is widely used as the kiln slab for firing porcelain (>1300℃), and its service life is more than double that of Clay-SiC.

③Mullite bonded silicon carbide products (Mullite-SiC)

Add α-Al2O3 micropowder and SiO2 micropowder to the ingredients of SiC, press molding, during the sintering process, Al2O3 and SiO2 are combined to form mullite; during use, SiO2 formed by oxidation of SiC also partly forms mullite with Al2O3. This material has good thermal shock stability and is widely used in the manufacture of porcelain saggers and slabs.

④Silicon nitride bonded silicon carbide products (Si3N4-SiC)

The metal silicon powder and SiC sand are mixed together, and after molding, they are fired under the protection of nitrogen. Si reacts with N2 to form Si3N4 to combine SiC. This material is widely used in the manufacture of silicon carbide bricks for blast furnaces, refractory kiln furniture, etc.

⑤Recrystallized silicon carbide products (R-SiC)

Using α-SiC as raw material, making α-SiC slurry through proper particle grading and adding effective surfactants, after pouring and molding (also press molding) in Ar atmosphere or vacuum sintering furnace at a high temperature above 2000 ℃ Under sintering, SiC evaporates and condenses and recrystallizes at the junction of SiC particles to bond the SiC particles together. It has high high temperature strength, strong oxidation resistance and good thermal shock stability, making it an excellent high temperature engineering material. The kilns in the ceramics and grinding wheel industries use R-SiC beams to build the kiln car, which can be used up to 1600°C.

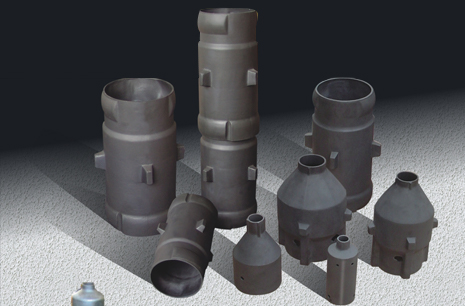

⑥Reaction sintered silicon carbide products (SiSiC)

Use α-SiC and graphite powder to mix in proportion, press or vacuum extrusion, heat to about 1650℃, infiltrate Si into the green body through liquid or gas phase, and make it react with graphite to form β-SiC. The particles combine to achieve densification. The characteristics of the material: a. There are no open pores, and O2 cannot penetrate into the material during use, so it has strong oxidation and corrosion resistance; b. The flexural strength at high temperature is twice that of R-SiC, and the load-bearing capacity Significantly improved: c. Very good thermal conductivity and wear resistance: d. Its volume stability is very good until the use temperature limit (1350℃); e. Due to infiltration of 10% to 20% of Si, its highest work The temperature does not exceed 1350%~1380℃, which is lower than R-SiC; f. The service life is 2 to 3 times that of Si-SiC. The use temperature of this material can meet the needs of most ceramics and grinding wheels firing, and it has become a new generation of kiln furniture materials, and has a great tendency to replace Si3N4-SiC and R-SiC kiln furniture.

The article is taken from the Internet, if there is any infringement, please contact to delete it!